Calcium Sulphate Raised Floor

Guaranteeing durability and versatility, our calcium sulphate raised floors are a top choice for commercial and industrial spaces. Arifeen Marble is a leading supplier and installer of raised floors in the UAE, offering a wide range of options including marble, tile, onyx, carpet, and travertine. Our expert team ensures a seamless installation process in Dubai, Ajman, Sharjah, Ras Al Khaimah, Fujairah, and Abu Dhabi. Trust Arifeen Marble for high-quality raised floors that meet your specific needs and exceed your expectations.

Calcium Sulfate Raised Access Flooring: A Sturdy and Flexible Flooring Option

Calcium sulfate raised access flooring is a durable and versatile flooring option that is commonly used in commercial and industrial settings. Made from a combination of calcium sulfate and other materials, this type of flooring is known for its strength and flexibility. It provides a stable and level surface for equipment and furniture, while also allowing for easy access to underfloor utilities such as wiring and plumbing. Calcium sulfate raised access flooring is easy to install and maintain, making it a popular choice for a wide range of applications.

Calcium Sulphate Elevated Flooring: A Robust and Adaptable Floor System

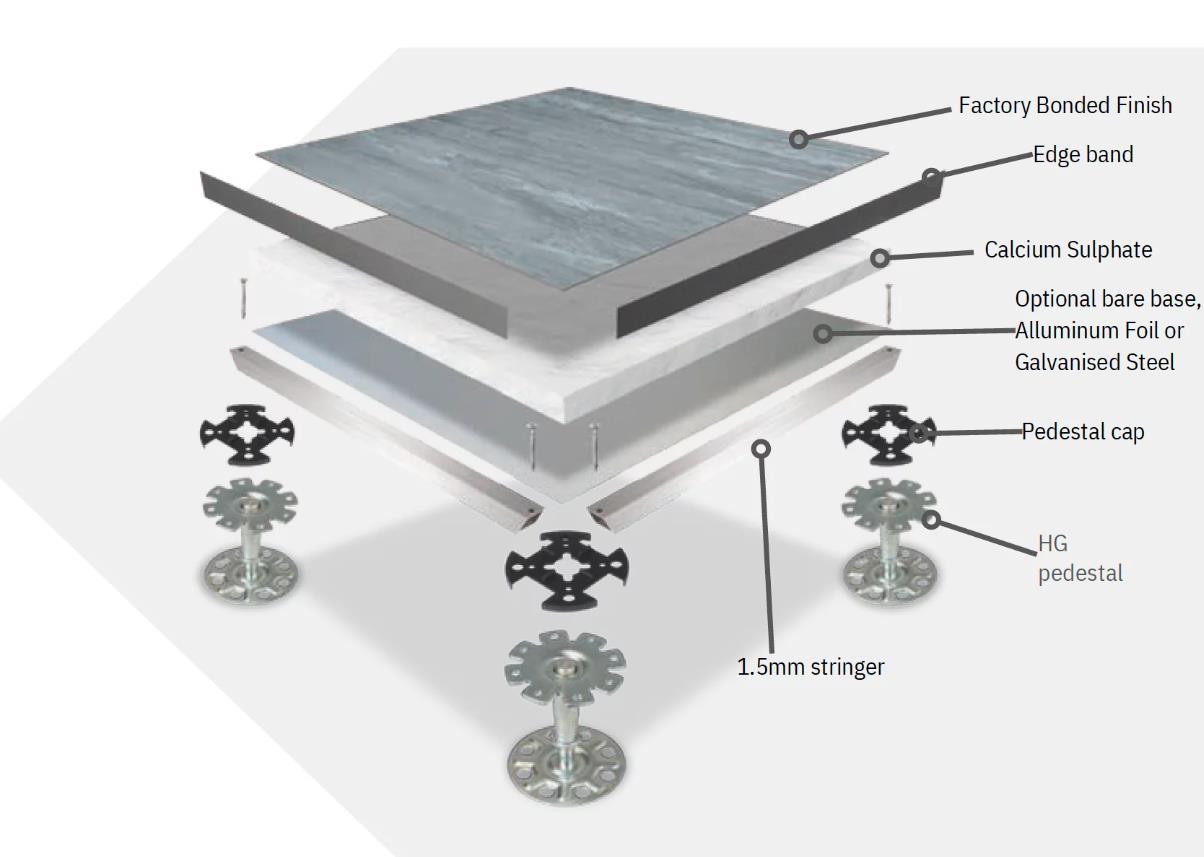

Calcium sulphate elevated flooring is a durable and versatile floor system that is commonly used in commercial and industrial settings. Made from calcium sulphate panels supported by adjustable pedestals, this type of flooring is known for its strength, stability, and adaptability. It can easily accommodate heavy loads, provide excellent sound insulation, and be easily customized to meet specific design requirements. Additionally, calcium sulphate elevated flooring is fire-resistant, environmentally friendly, and easy to install and maintain, making it a popular choice for a wide range of applications.

Types of Calcium Sulphate Raised Floor Systems

There are two main types of Calcium Sulphate Raised Floor Systems: 1. Hollow Core Calcium Sulphate Raised Floor System 2. Solid Core Calcium Sulphate Raised Floor System

Hollow Core Calcium Sulphate Raised Floor System

This type of raised floor system consists of hollow core panels made of calcium sulphate. These panels are lightweight yet durable, making them ideal for use in commercial and industrial buildings. The hollow core design allows for easy installation of cables and wires underneath the floor, providing a clean and organized workspace.

Solid Core Calcium Sulphate Raised Floor System

Solid core calcium sulphate raised floor systems are made of solid panels that offer increased strength and stability compared to hollow core systems. These panels are suitable for heavy-duty applications and can support heavier loads. Solid core systems are often used in data centers, server rooms, and other high-traffic areas where durability is essential. Overall, both types of calcium sulphate raised floor systems provide excellent performance in terms of strength, durability, and flexibility for cable management. Choose the type that best suits your specific needs and requirements.

calcium sulphate raised floor Price in Dubai

| Company Name | Price (AED) |

|---|---|

| Al Nasr Technical Trading | 150 |

| Al Ameen Steel Fabrication | 180 |

| Al Mulla Industries | 160 |

| Arifeen Marble | GET qoutation |

calcium sulphate raised floor Cutting

For all your calcium sulphate raised floor cutting needs, look no further than Arifeen Marble. We are a leading installer, supplier, and polisher of marble, tile, onyx, raised floor, carpet, and travertine in the UAE. Our team of experts is dedicated to providing top-notch services in Dubai, Ajman, Sharjah, Ras Al Khaimah, Fujairah, and Abu Dhabi. Trust Arifeen Marble for all your flooring needs and experience the difference in quality and craftsmanship. Contact us today for a consultation and let us elevate your space with our premium services.

calcium sulphate raised floor Installation

At Arifeen Marble, we are proud to offer top-notch installation services for calcium sulphate raised floors in the UAE. Our team of experts is highly skilled and experienced in handling all types of flooring materials, including marble, tile, onyx, carpet, and travertine. We ensure that every installation is done with precision and care to guarantee a flawless finish. With our services available in Dubai, Ajman, Sharjah, Ras Al Khaimah, Fujairah, and Abu Dhabi, we are your go-to choice for all your flooring needs. Trust Arifeen Marble for quality workmanship and exceptional customer service.

calcium sulphate raised floor Polishing

At Arifeen Marble, we are proud to offer top-notch polishing services for calcium sulphate raised floors. Our team of experts is highly skilled in the art of marble, tile, onyx, carpet, and travertine installation, supply, and polishing. With years of experience in the industry, we have established ourselves as a trusted name in the UAE, serving clients in Dubai, Ajman, Sharjah, Ras Al Khaimah, Fujairah, and Abu Dhabi. When it comes to enhancing the beauty and durability of your raised floor, trust Arifeen Marble to deliver exceptional results every time. Contact us today to learn more about our services and how we can help transform your space.

FAQs

What are the benefits of using calcium sulphate raised floors in commercial or industrial buildings?

Benefits of Using Calcium Sulphate Raised Floors

– Enhanced durability and strength – Excellent fire resistance properties – Improved sound insulation – Easy installation and maintenance – Environmentally friendly and recyclable – Provides a stable and level surface for equipment Overall, calcium sulphate raised floors offer a range of benefits that make them a popular choice for commercial and industrial buildings.

How does the installation process of calcium sulphate raised floors differ from other types of raised flooring systems?

Installation Process of Calcium Sulphate Raised Floors

The installation process of calcium sulphate raised floors differs from other types of raised flooring systems in several ways:

- Preparation of Subfloor: The subfloor must be clean, level, and free of any debris before installing calcium sulphate raised floors.

- Panel Placement: Calcium sulphate panels are placed on adjustable pedestals, ensuring a stable and even surface.

- Panel Interlocking: The panels are interlocked using a tongue and groove system, providing a seamless finish.

- Finishing Touches: Once the panels are in place, the flooring system is ready for use, with the option to add additional finishes such as carpet or vinyl tiles.

What are the key considerations to keep in mind when selecting a calcium sulphate raised floor for a specific commercial or industrial application?

Key Considerations for Selecting a Calcium Sulphate Raised Floor

When selecting a calcium sulphate raised floor for a specific commercial or industrial application, there are several key considerations to keep in mind:

- Load-bearing capacity: Ensure that the raised floor system can support the weight of equipment, furniture, and foot traffic in the space.

- Fire resistance: Calcium sulphate raised floors are known for their fire-resistant properties, making them ideal for applications where fire safety is a concern.

- Moisture resistance: Consider the level of moisture in the environment and choose a raised floor system that can withstand moisture without warping or deteriorating.

- Acoustic properties: If noise reduction is important in the space, look for a raised floor system that offers good acoustic insulation.

- Installation and maintenance: Consider the ease of installation and maintenance of the raised floor system, as well as any additional costs associated with these processes.

What are the potential drawbacks or limitations of using calcium sulphate raised floors in commercial or industrial buildings?

Potential Drawbacks or Limitations of Using Calcium Sulphate Raised Floors

- Cost: Calcium sulphate raised floors can be more expensive to install compared to other types of raised flooring systems.

- Weight Limitations: Calcium sulphate panels have weight limitations, which may restrict the types of equipment or furniture that can be placed on the raised floor.

- Moisture Sensitivity: Calcium sulphate panels are sensitive to moisture and may warp or degrade if exposed to water or high humidity levels.

- Limited Design Options: Calcium sulphate raised floors may have limited design options compared to other types of raised flooring systems, which could impact the overall aesthetics of the space.

- Maintenance: Calcium sulphate panels may require more maintenance compared to other types of raised flooring systems, as they can be more prone to damage or wear over time.

What are the specific maintenance requirements for calcium sulphate raised floors in commercial or industrial buildings?

Maintenance Requirements for Calcium Sulphate Raised Floors

1. Regular Cleaning: The raised floor panels should be regularly cleaned to remove dust, dirt, and debris. This can be done using a vacuum cleaner or a damp mop.

2. Avoid Water Damage: Calcium sulphate raised floors are susceptible to water damage, so it is important to avoid spills and leaks. If water does come into contact with the panels, it should be cleaned up immediately to prevent warping or swelling.

3. Inspect for Damage: Regularly inspect the raised floor panels for any signs of damage, such as cracks, chips, or loose tiles. Any damaged panels should be replaced promptly to maintain the structural integrity of the floor.

4. Preventative Maintenance: In addition to regular cleaning and inspections, preventative maintenance measures should be taken to prolong the lifespan of the raised floor. This may include applying a protective sealant or coating to the panels.